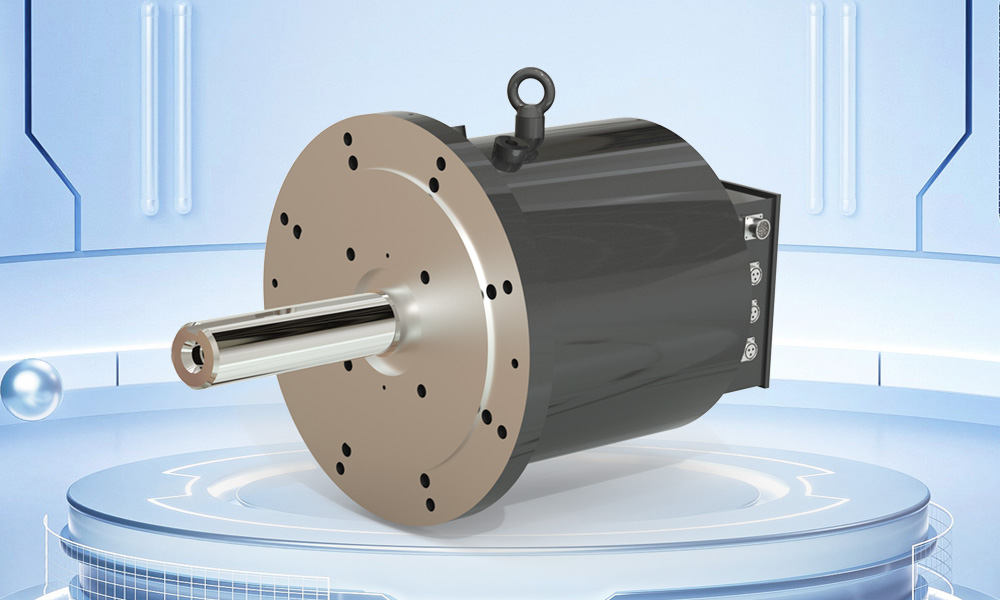

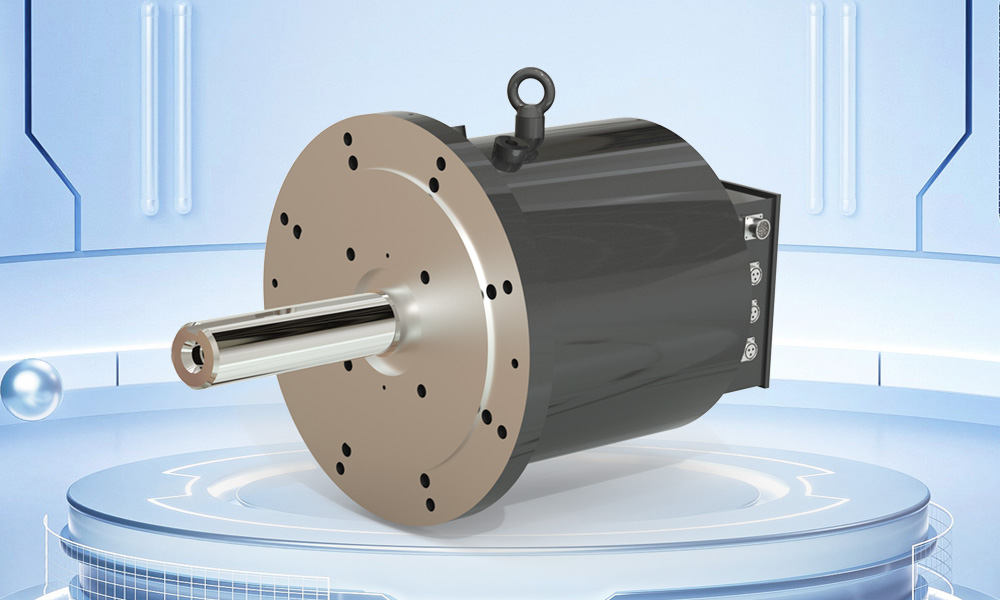

The manufacturing of permanent magnet direct drive motors is a complex and delicate process that involves multiple key steps and components.

The manufacturing difficulty is mainly reflected in the following aspects:

1. Electromagnetic design: Determining the magnetic circuit structure and coil layout of a permanent magnet motor, as well as the structural design of the rotor and stator, is a complex and meticulous process. This requires a deep understanding of electromagnetic field theory and rich practical experience to ensure that the motor performance meets the design requirements.

2. Raw material procurement and processing: The manufacturing of permanent magnet direct drive motors requires the use of various raw materials, such as motor cores, permanent magnet materials, insulation materials, and coil materials. Especially for permanent magnet materials, their magnetization treatment and quality control are crucial to the performance of motors. In addition, the machining accuracy requirements for various components are high, requiring the use of advanced machining equipment and processes.

3. Permanent magnet assembly: Permanent magnet assembly is the installation and magnetization treatment of the processed rotor and stator with permanent magnets. This process requires strict control of assembly quality to ensure that the position, direction, and magnetization strength of the permanent magnet meet the requirements.

4. Winding coil: The coil is an important component of the motor, and its winding quality and wiring method directly affect the performance of the motor. Therefore, the winding of the coil needs to strictly follow the design requirements and undergo necessary insulation treatment.

5. Final installation and debugging: In the final stage of the motor, final installation and debugging are required. This includes fixing the stator and rotor, installing bearings and safety devices, etc. During the debugging process, it is necessary to test and adjust the various performance of the motor to ensure its normal operation and meet the performance requirements.

In summary, the manufacturing difficulty of permanent magnet direct drive motors is reflected in multiple aspects, including electromagnetic design, raw material procurement and processing, permanent magnet assembly, winding coils, final assembly and debugging, etc. These steps require a high degree of professionalism and meticulous operation to ensure the performance and quality of the motor.

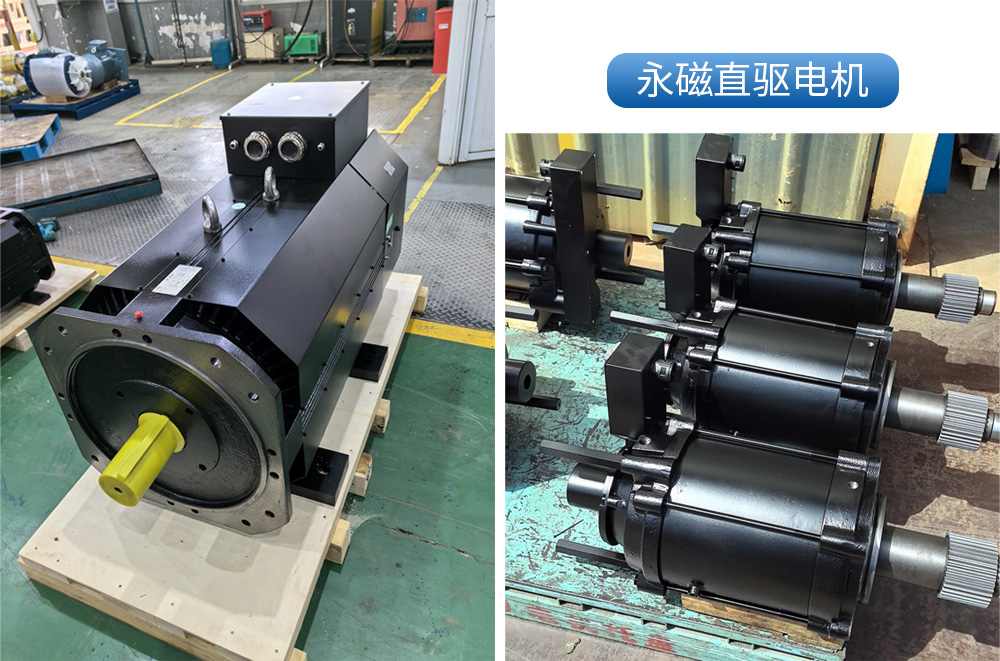

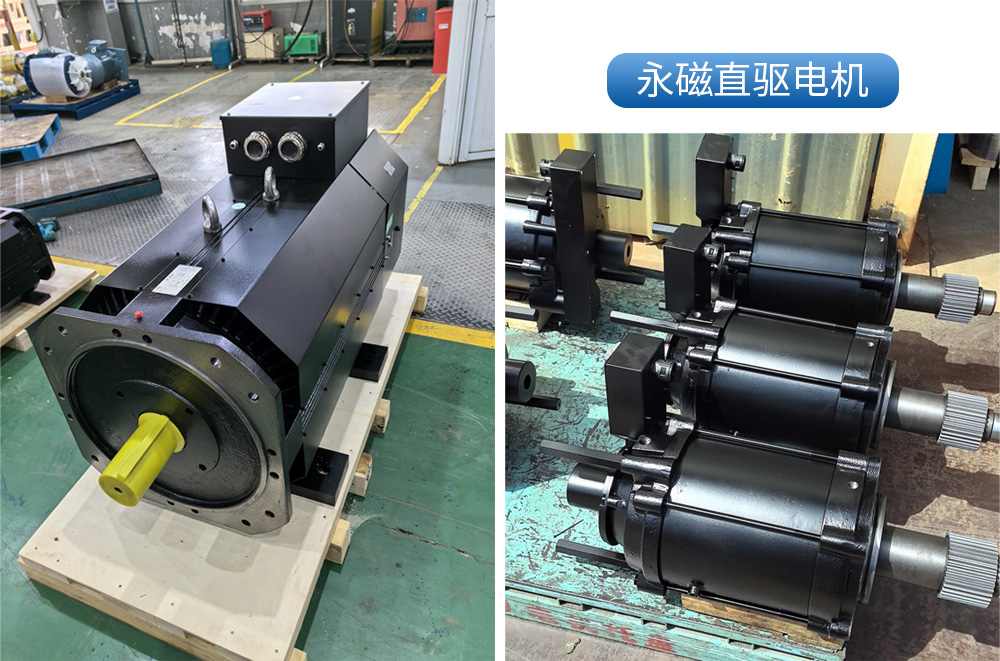

Hengda Electric has always been dedicated to the research and development, production, and service of permanent magnet direct drive motors. With advanced technology and equipment, lean manufacturing processes, reliable product quality, and satisfactory after-sales service, the company provides customers with the most suitable professional motor solutions and creates greater social value.